High Efficiency Airless (HEA) technology is a revolutionary spray tip technology. It was designed by a team of engineers that were determined to develop an airless tip that would perform the same as traditional airless, but at half the psi (psi refers to the pressure at which the sprayer operates). This means:

- Longer sprayer and tip life due to lower pressures causing less strain on the unit

- Improved control with less bounce back when pulling the trigger

- Less wasted paint (and dollars) due to less overspray

Those benefits were the driving force behind developing this new technology. It is our goal to continuously improve and provide customers with the best experience.

Timeline

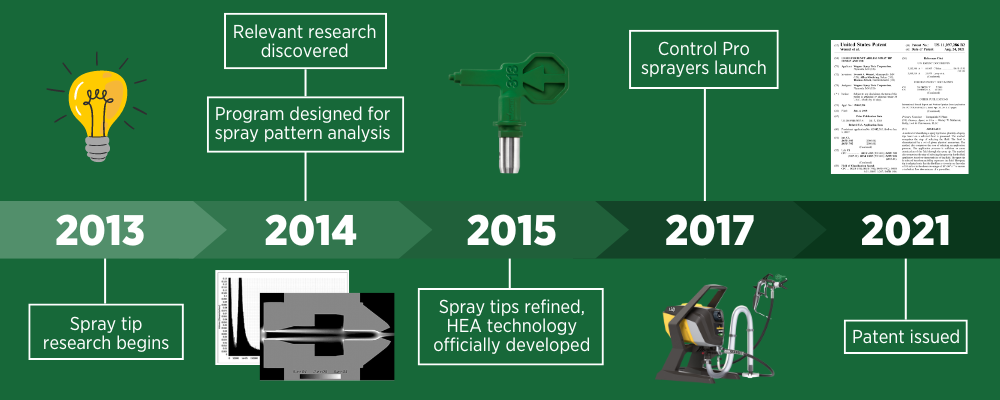

| DATE | EVENT |

|---|---|

| 2013 | SPRAY TIP RESEARCH BEGINS Existing spray tip technology had issues spraying at 1000 psi, so Wagner engineers collaborated with University of Minnesota students to develop new tip technology. |

| 2014 | RELEVANT RESEARCH DISCOVERED Wagner engineers discovered similar research was being conducted by a team at the University of Minnesota. Their goal was to develop fertilizer spray tips for the agricultural industry that produced a large enough particle size to reach the plant without drifting away in the wind while still achieving even distribution. |

| PROGRAM DESIGNED FOR SPRAY PATTERN ANALYSIS An aerospace engineer from the University of Minnesota began working at Wagner and developed prototypes along with her husband who has a doctorate from MIT. They developed a program to spray, scan, and grade spray patterns to take the guesswork out of which tip sprays better than the next. | |

| SPRAY TIPS DEVELOPED After laying the groundwork, she went to work as a research engineer at Ford Motor Company. Another engineer who worked on the initial spray tip research from the University of Minnesota was brought in to continue developing the spray tips. | |

| 2015 | SPRAY TIPS REFINED The tips were improved and refined to spray almost every latex paint at a pressure below 1000 psi. High Efficiency Airless technology had been developed! This engineer went on to work with NASA. |

| 2017 | CONTROL PRO SPRAYERS LAUNCH Wagner Control Pro sprayers launch featuring High Efficiency Airless technology. Thousands of homeowners are now able to accomplish their DIY projects at lower pressures while painting like a pro. |

| 2021 | PATENT ISSUED Wagner High Efficiency Airless tip patent was issued. |

Watch Videos to Learn More

What Customers Are Saying

Now, HEA technology is available exclusively on Wagner Control Pro and Titan ControlMax paint sprayers. You can try it for yourself and harness the benefits like these customers did:

| “I’m a landscape professional and I most often use the Control Pro 130 to stain raised garden boxes, trellises, and fences. I highly recommend this for medium sized jobs. Stain sprays evenly and clean up is easy.” -Steve, Control Pro 130 |

| “Started painting my living room with a roller and after two coats I went and purchased the Wagner Control Pro 130. I was able to complete the entire room in less than an hour.” -JR, Control Pro 130 |

| “In the past I have used a paint brush and it was an all day project. The Wagner Control Pro 170 made the painting process only take about an hour. I like how well it covered the railing and it got into the small cracks and areas that brush painting did not do. The finish was smooth and the railing looks like new […] I would definitely recommend this product to anyone considering a painting project like doing railings or a larger surface like a fence, house or a wall.” -Clark, Control Pro 170 |

| “If you’re a DIYer or a pro, this sprayer’s your best buddy for a flawless paint job! I’ve sprayed over 100 gallons of exterior acrylic paint and over 100 gallons of stain with it and I’ve had no issues. Just kept up with proper maintenance and cleaning.” -Trevor, Titan ControlMax 1900 Pro |

Products Using HEA Technology

Displaying slide of 4